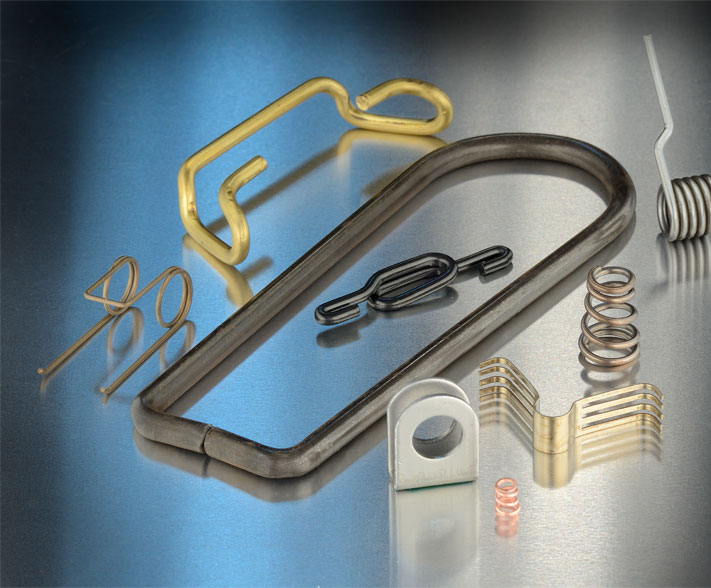

Our fourslide process combines forming in multiple planes with typical power press operations of piercing, blanking and gutting. Using wire or strip material, our in-house tool design and build team will create custom tools for your part. We can work in any alloy; carbon steel, stainless steel, brass, copper, aluminum, elgiloy, inconel, the list goes on to include wire of special shapes.

Fourslide machine equipment can bend or form metal in similar fashion to a conventional stamping press however we can accomplish complicated shapes with lower tooling cost and less raw material. This is possible because of the manner in which the raw material in fed into a fourslide. The grip and hold feed mechanism allows the designer to eliminate the carrying strip (sometimes referred to as the “skeleton”) in most cases. More efficient material utilization means lower production cost.

Fourslide machines are best in production runs above 10,000 pieces since there is hard tooling and machine set-up involved. As new designs move into higher volume production, fourslide machine can make parts complete and eliminate costly manual operations. In volumes above 100,000 our fourslide process can really shine with low piece price and consistent, repeatable quality.

The concept for these machines was developed decades ago on sound forming principles which, of course, remain valid today. Over the years numerous upgrades and additions have occurred. We can add additional slides from various directions, extend feed lengths, thread holes, drill or finish ends of wire, bend in three planes, and more.

Our equipment can form wire .15mm – 6.3 mm (.006” – .250”) diameter; strip material .13mm – 3mm (.005” – .125”) thick and a maximum width of 56mm (2.20”).

New England Spring can provide design suggestions for your part which can save time & money, improve performance and alleviate manufacturing problems. We’re proud of our history of working with engineers and designers to bring a design from the early stages of part development through successful product launch. Our tool design and build team has hundreds of hours of accumulated experience to apply to your application. What can we do for you?